Wet processing, a pivotal method in coffee production, plays a crucial role in defining the coffee’s final quality and flavor. This method, also known as the washed process, involves cleaning the coffee beans thoroughly, removing the cherry and mucilage layers before drying.

Primarily used for premium coffees, wet processing is esteemed for its ability to enhance the intrinsic qualities of the coffee bean, offering a purer and more refined taste.

Key Takeaways

- Flavor and Consistency: Wet processing is renowned for yielding a cleaner, more consistent flavor profile. By removing all fruit residue, it allows the bean’s natural flavor to shine, reducing the risk of fermentation-related defects.

- Resource Intensive: This method demands significant water and labor, distinguishing it from less intensive methods like dry processing. The extensive use of water and meticulous labor underscores the commitment to quality inherent in wet processing.

- Comprehensive Process: The process encompasses several stages, including harvesting, pulping, fermenting, washing, drying, and milling. Each step is critical in achieving the desired quality and flavor.

- Environmental Impact: Given its high water usage, wet processing raises environmental concerns. Sustainable practices and innovations are essential to mitigate its ecological footprint, ensuring the coffee industry’s long-term viability.

The Process of Wet Processing Coffee Beans

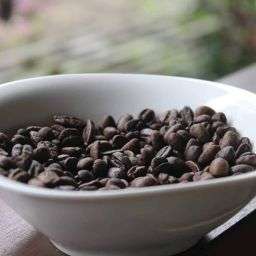

Wet processing, a method distinct from its dry and honey counterparts, involves several intricate steps to prepare coffee beans for the market. The process begins with harvesting, where only the ripest cherries are selected, ensuring uniformity in flavor. Once harvested, the pulping stage removes the outer skin of the cherries, exposing the bean and mucilage.

The subsequent fermentation phase is crucial, as the beans are soaked in water, allowing the mucilage to dissolve—a step that significantly impacts the bean’s flavor profile. After fermentation, the beans are washed thoroughly to eliminate any remaining mucilage, followed by drying, which can be done using sun-drying methods or mechanical dryers. The final step, milling, removes the parchment layer, revealing the green coffee bean ready for roasting.

Compared to dry processing, which involves sun-drying the whole cherry, and honey processing, where some mucilage is left on the bean, wet processing is more labor-intensive and water-reliant. However, this method offers greater control over the fermentation process, reducing the risk of defects and enhancing flavor consistency.

Flavor Profile and Quality

Wet processing significantly influences the coffee’s flavor, acidity, and body. By removing all fruit residue before drying, wet-processed beans typically exhibit a cleaner, more pronounced acidity and a lighter body compared to dry-processed beans, which retain more fruity flavors.

The removal of the mucilage and cherry layers through washing and fermentation allows the bean’s inherent flavors to come to the forefront, leading to a more refined and consistent taste profile.

This method’s impact on quality is notable, as it generally results in fewer defects and a more uniform product. The meticulous control over each processing stage allows producers to replicate successful flavor profiles, ensuring a consistent product batch after batch.

As a result, wet-processed coffees are often preferred for their clarity and complexity, particularly in single-origin coffees where highlighting the bean’s intrinsic characteristics is desired.

Environmental Impact and Sustainability

Wet processing of coffee beans, while beneficial for flavor and quality, raises environmental concerns due to its high water usage. The method requires substantial amounts of water for washing and fermenting the beans, which can lead to water wastage and pollution if not managed properly. The resultant wastewater, if not treated, can contaminate local water sources with organic materials and chemicals.

To address these concerns, the coffee industry is exploring sustainable practices and innovations. Water recycling systems and the use of eco-friendly machinery that reduces water usage are becoming more common. Some producers are adopting microbial fermentation processes that require less water.

Additionally, the by-products of wet processing, like pulp and mucilage, are being repurposed as compost or biogas, turning waste into resources and reducing the overall environmental footprint of coffee production.

Global Perspectives on Wet Processing

Wet processing techniques vary globally, influenced by regional climates, traditions, and technological advancements. In countries like Colombia and Ethiopia, traditional methods are often combined with modern techniques to enhance efficiency while preserving the unique flavors of their beans. For instance, Colombia has developed eco-pulpers that use less water, aligning with their commitment to environmental sustainability.

In contrast, countries like Kenya and Costa Rica are known for their meticulous wet processing methods, which contribute to their coffees’ distinct profiles. Kenya uses a double fermentation process, which is believed to enhance the coffee’s brightness and complexity. Costa Rica, particularly known for its honey-processed coffees, applies variations of wet processing to achieve different flavor profiles, demonstrating the method’s versatility.

These global variations highlight the adaptability of wet processing to different environmental and cultural contexts, showcasing the coffee industry’s innovation in pursuit of quality and sustainability.

The Market for Wet Processed Coffee

Consumer preferences are increasingly leaning towards wet processed coffee, driven by its reputation for cleaner and more nuanced flavors. This shift is reflected in the market demand, with wet processed coffees often commanding higher prices due to their perceived quality and the intensive labor and resources required for their production.

The nuanced flavor profiles, consistent quality, and the specialty coffee movement’s rise contribute to this trend, influencing consumers to seek out wet processed coffees for a superior tasting experience.

FAQs

Q: How does wet processing affect coffee flavor compared to dry processing?

A: Wet processing typically results in a cleaner, more acidic, and more flavorful cup compared to dry processing, which offers a fruitier and sometimes more robust flavor profile.

Q: Is wet processing more environmentally harmful than other methods?

A: While it uses more water, innovations and sustainable practices are being implemented to reduce its environmental impact.

Q: Why is wet processed coffee often more expensive?

A: The intensive labor, higher water usage, and the meticulous steps involved in wet processing contribute to the higher cost of these coffees.

Final Thoughts

Understanding the wet processing method is crucial for both consumers and producers, highlighting its impact on flavor, quality, and sustainability. As the coffee industry evolves, the emphasis on sustainable practices and the ability to appreciate the nuances of different processing methods will continue to shape the market and consumer preferences. Embracing these complexities allows for a deeper appreciation of coffee and its journey from bean to cup.